Khalfan Juma Belhoul, CEO of Dubai Future Foundation, confirmed that the “M061” project launched by the Foundation with the aim of developing an innovative Emirati model of respirators by a specialized scientific team of national and global competencies, represents one of the outputs of the Foundation’s initiatives to support the first line of defence in the UAE and enhance Its capabilities to provide health services at the highest standards.

Khalfan Belhoul said that the directives of His Highness Sheikh Hamdan bin Mohammed bin Rashid Al Maktoum, Crown Prince of Dubai and Chairman of the Executive Council and Chairman of the Board of Trustees of the Dubai Foundation for the Future, and his support, was a catalyst for the efforts of the team that was able to implement the project within a short period to support the efforts of the health sector in the UAE in the face of The challenges of the emerging coronavirus “Covid-19“, and maintaining the health and safety of community members.

He pointed out that the idea of the project started with increasing pressure on health care systems worldwide due to the Corona pandemic, which caused a significant shortage in many countries in the vital medical supplies and respirators that play a major role in treating severe cases, which encouraged the Dubai Foundation for the Future To form a team of engineers, programmers and experts to communicate with healthcare providers and cooperate with them in developing a pilot model for a respirator with international standards.

Dubai Future Foundation

An Emirati science project led by Dubai Future Foundation to support the efforts of the health sector in the country

Open-source platform

Khalfan Belhoul stressed that the project provides an open-source platform that includes detailed information about respirators that can be easily accessed via the Internet from anywhere in the world, reflecting the UAE’s commitment to providing the efforts of health, scientific and technological sectors and cooperation with various countries, governments, institutions and private companies in facing “Covid-19“.

Efficiency and durability

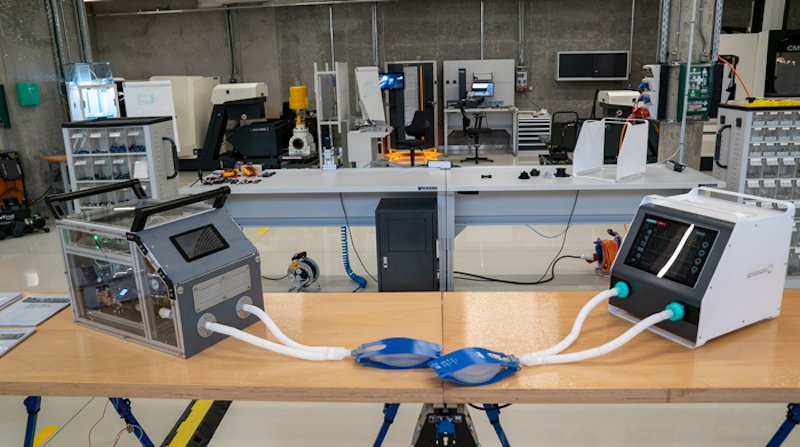

The “M061” project team worked over the course of eight weeks to develop a respirator based on components available in the available supply chains, which could be easily assembled and developed according to need, and the team studied the designs of existing respirators, focusing on the effectiveness and durability factors.

The design phase focused on developing robust, scalable devices due to their vital role in maintaining the stability of the case of people living with the virus, and giving their bodies time to cope and recover from infection, especially when the patient becomes unable to breathe spontaneously.

Multiple functions

The device performs this task by pushing air into the patient’s lungs to get enough oxygen and help him get rid of carbon dioxide at the same time.

The device “M061” includes several sub-systems integrated together in order to perform its medical function very effectively, as the respiratory cycle ensures the ability to breathe the patient and control the inhale and exhale, during inspiration, the device is mixed with air and compressed oxygen to achieve the required oxygen concentration which ranges from 21% To 100% and pushes it into the patient’s lungs according to the appropriate settings.

There are two main types of artificial respiration, the first type known as “pressure ventilator”, which controls the pressure of air and oxygen flowing into the lungs to prevent complications known as respiratory lung injury. The second type is “ventilator by volume,” which includes controlling the volume of air flowing into the lungs precisely.

During exhalation, the device pulls the air out of the patient’s lungs in a controlled manner in order to maintain the pressure inside them so that the alveoli do not collapse, and the device keeps pace with the patient’s condition, if he is anaesthetized and needs a specific respiratory cycle, or needs automatic respiratory assistance.

High standards

The team was keen to adhere to the standards followed globally for the development of the ventilator, because measurements, such as the maximum permissible pressure during inhalation and the volume of air, the ratio between the inhalation and exhalation stages of the respiratory cycle, the value of intra-lung pressure after expiry and the maximum amount of air flowing during the minute and different types of breathing, It affects the design of the ventilator and the selection of its components.

The device “M061” meets the needs of each patient because it offers many types of artificial respiration, such as pressure breathing, volume breathing and spontaneous breathing, and the doctor chooses the appropriate type for the patient according to his health condition, as the device provides invasive and non-invasive breathing for periods of hours to weeks.

The efficiency of the device

The “M061” device is specially designed with standard parts and replaceable components that are easily accessible, which helps in solving the problem of lack of medical supplies, the most important of which is the global respirators, and also meets the standards of the rapidly manufactured ventilators set by the Medicines and Healthcare Products Regulatory Agency in In the United Kingdom, the electronic circuit includes sensors input and output, power source, and more.

The “M061” was designed to respond to the epidemic shortage and relieve stress on healthcare systems by supporting hospital respirators, not replacing them.

How M061 works

The “M061” device consists of a mechanical airway made of tubes equipped with valves, sensors and purifying membranes necessary to achieve respiratory support for the patient, and valves operate to open and close air passages to control the amount of air, while sensors, such as pressure sensors and flow sensors, transmit patient status data to a platform that controls In the respiratory cycle, the membranes filter the air to reach the patient pure.

Technology employment

The “M061” team designed a multi-layer electronic circuit that includes a computer and digital interfaces to support the development of a respirator equipped with a touch screen used by doctors to operate and control the device, and the team followed professional engineering methods during the development of the device to ensure its conformity to the highest quality standards in preparation for the accreditation process, keeping in mind Requirements for respiratory specialists who treat “Covid-19” patients and have significant experience in the field of the ventilator.

The team plans to conduct field tests and experiments in cooperation with respiratory specialists and doctors in Dubai hospitals and to conduct patient tests after the success of the tests that the device will undergo to ensure patient safety.

Emirati and international competencies

The scientific team responsible for the development of the project included a group of Emirati and international talents, who are: Khalifa Al Qama, Saqr Bin Ghaleb, Maryam Buhamid, Tariq Taha, Rashid Al Suwaidi, Muhammad Al Zahmi, Majid Al-Khatib, Hamad Muhammad, Leith Mahdi, Alexander Spice and Julian Verling.

The project was implemented in partnership between the Dubai Future Foundation, the Office of Artificial Intelligence in the UAE government, the Control Center for Coronavirus Control in Dubai, the Ministry of Health and Community Protection, the Dubai Health Department, the Mohammed Bin Rashid University of Medicine and Health Sciences, and several government agencies, research centers and institutions Global and other startups.